OUR PROCESS

Our salt making is a unique and innovative process

step 1

We draw up brine from the Iapetus Ocean, deep below the Appalachian Mountains, to the surface by means of a well. The brine is held in a settling tank for about a week to let it clarify.

step 2

The brine is then moved from the tank into evaporation beds in our sun-houses, where it is solar evaporated to concentrate the salinity.

step 3

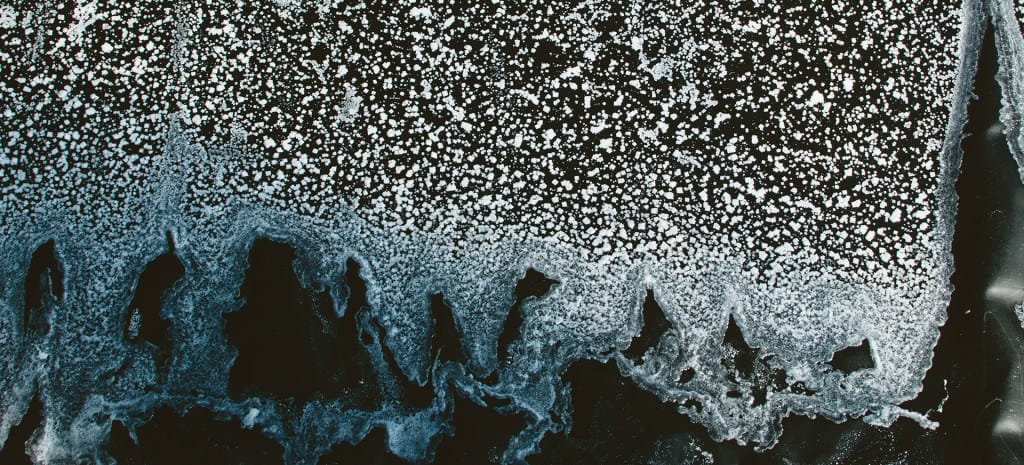

Once the brine is evaporated by just the right amount, it is moved to a crystallization bed. Then crystals begin to form. (The fun part!)

step 4

Once the salt crystals have formed, they are hand-raked to separate them from the bittern ("nigari", as it is known in Japan). This is a residual mineral-rich liquid that can be used to make tofu or can be taken as a natural mineral supplement.

step 5

Our hand-made wooden rake is the perfect tool to gently harvest the salt and optimize the size and flake of the crystals. All of our tools are hand-crafted for us from Birch wood by our good friends at Allegheny Treenware, in Thornton, WV.

step 6

At the end of the harvesting the salt is scooped onto cotton cloths for drying.

step 7

Salt is harvested daily in the summer.

step 8

Finally, we carry the salt in small wagons back to our farm office, for it’s last breath of fresh air before we package, hand-label, batch number, and seal each glass jar of salt with the same care with which it was made.